Pulse tube cryocoolers vs.

Gifford-McMahon cryocoolers

Three main differences exist between pulse-tube cryocoolers (PT) and Gifford-McMahon cryocoolers (GM).

- Price—In general, GM cryocoolers are less expensive than PT cryocoolers of similar cooling power.

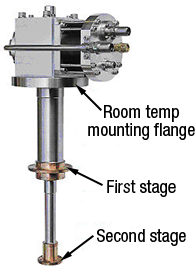

- Vibration—Both GM and PT cryocoolers are mechanical refrigerators that do have some level of vibration. Two locations exist on the cold head where vibration is important: The room temperature mounting flange and the second stage (see photo).

- Orientation—The performance of PT cryocoolers is orientation-dependent. PT cryocoolers only function properly when they are operated in a purely vertical orientation with the second stage pointing down. GM cryocoolers will lose some cooling power when the cold head is not operated vertically, but the base temperature will not be affected. GM cryocoolers can operate in any orientation.

|  |

SHI RDK-101D 0.2 W at 4.2 K Gifford-McMahon cold head | SHI RP-062B 0.5 W at 4.2 K pulse-tube cold head |

The room temperature mounting flange provides the interface for a vacuum shroud or vacuum chamber. Vibrations at the room temperature mounting flange will be transmitted to the vacuum shroud and anything else the shroud is physically contacting.

This is important if the cryocooler is rigidly mounted on other instruments that are sensitive to vibrations. An example would be a cryocooler installed in the evacuated sample compartment of an FTIR spectrometer. Any vibrations from this room-temperature mounting flange would be transmitted through the vacuum shroud to the spectrometer. These vibrations may cause damage or misalignment to the delicate optics inside the spectrometer.

When a cryocooler is mounted on a delicate instrument such as the FTIR spectrometer, a PT system would be a better choice than a GM system because the vibration level at the room temperature mounting flange of a PT system is significantly lower than in a GM system.

The sample being cooled is usually mounted onto the second stage. Any vibrations from the second stage will be transmitted directly to the sample.

GM cold heads have vibrations at the second stage on the order of 20 µm along the axis of the cold head. GM cold heads have vibrations on the order of ~5 µm perpendicular to the axis of the cold head.

Pulse-tube cold heads have vibrations on the order of 4 to 7 µm along the axis of the cold head and ~2 µm perpendicular to the axis of the cold head.

Unlike GM cold heads, PT cold heads do not have any internal moving parts to add to the vibration levels of the cold head. However, expansion of the compressed helium gas inside each stage of the cold head does contribute to the vibration level at the second stage. This is true for both PT and GM cold heads.

The valve motor on GM cold heads is always bolted to this room-temperature mounting flange. As the motor turns, the valve is opened and closed. This same motor also drives the pistons (displacers) inside the first and second-stage cylinders.

The vibrations from this valve motor will contribute to the overall level of vibrations of the cold head. The movement of the displacers may also contribute to the vibrations at this flange on a GM cold head.

The valve motor on some PT cold heads does have moving parts to open and close the rotary valve, although a “remote valve option” is available for the SHI RP-062B and all Cryomech PT systems allowing the valve motor to be mounted externally from the cold head, reducing vibrations from the motor.

A PT system would be a better choice if:

- Vibrations at the sample must be less than 20 µm.

- Vibrations from the cold head must be isolated from other equipment interfacing with the cryostat.

A GM system may be a better choice if:

- Vibrations on the order of 20 µm at the sample are acceptable.

- The cryostat will not be rigidly mounted to any equipment that is sensitive to mechanical vibrations.

- A base temperature of 4 K or below is necessary, but a PT system is beyond the budget limitations.

- The cold head will not be oriented vertically with the second stage pointing down.

If vibrations at the sample must be less than 5 µm, Lake Shore has a special design for a vibration-isolated exchange gas-cooled system. This system includes a 4 K, 7 K, or 10 K GM cold head with a special exchange gas vibration isolation system that reduces the vibration at the sample mount to less than 50 nm. The cryocooler does not physically contact the sample area, so vibrations from the cold head are essentially isolated from the sample. Because there is no physical contact between the cold head and the sample mount in this system, there is no incentive to use a more expensive PT cryocooler when a GM cryocooler will offer the same vibrational performance at a lower price.

4 K pulse tube cryocoolers offered by Lake Shore

| Model | Cooling power at 4.2 K | Compressor cooling | Remote valve |

| SHI RP-062BS | 0.4 W | Water | Yes |

| SHI RP-062B | 0.5 W | Water | No |

| SHI RP-082B2S | 0.9 W | Water and air (outdoor only for air-cooled compressor) | Yes |

| SHI-RP-082B2 | 1.0 W | Water and air (outdoor only for air-cooled compressor) | No |

| SHI RP-182B2S | 1.5 W | Water | No |

| Cryomech PT-403RM | 0.22 W | Water and air | Yes |

| Cryomech PT-403 | 0.25 W | Water and air | No |

| Cryomech PT-405RM | ~0.4 W | Water and air | Yes |

| Cryomech PT-405 | 0.5 W | Water and air | No |

| Cryomech PT-407RM | 0.45 W | Water and air | Yes |

| Cryomech PT-407 | 0.7 W | Water and air | No |

| Cryomech PT-410RM | <0.9 W | Water | Yes |

| Cryomech PT-410 | 1.0 W | Water | No |

| Cryomech PT-415RM | <1.3 W | Water | Yes |

| Cryomech PT-415 | 1.5 W | Water | No |

| Cryomech PT-420RM | <2.0 W | Water | Yes |

| Cryomech PT-420 | 2.0 W | Water | No |

| Cryomech PT-425RM | <2.5 W | Water | Yes |

| Cryomech PT-425 | 2.5 W | Water | No |

4 K Sumitomo Gifford-McMahon cryocoolers offered by Lake Shore

| Model | Cooling power at 4.2 K | Compressor cooling |

| RDK-101 | 0.2 W or 0.1 W | Water and air |

| RDK-205 | 0.5 W or 0.7 W | Water and air |

| RDK-305 | 0.4 W | Water and air (outdoor only for air-cooled compressor) |

| RDK-408 | 1.0 W | Water or air |

| RDK-412 | 1.25 W | Water or air |

| RDK-415 | 1.5 W | Water or air |

| RDK-418D4 | 2.0 W | Water or air |

10 K cryocoolers are also available.

Need a custom-engineered cryogenic system? We can help with that.

What is the difference between a pulse tube and a GM cryocooler?

Pulse tube and Gifford-McMahon (GM) cryocoolers are both closed-cycle refrigeration systems used to achieve cryogenic temperatures, but they differ significantly in design and performance characteristics. The most fundamental distinction lies in the presence of moving parts within the cold head. Pulse tube cryocoolers have no moving components in the cold region, which results in extremely low vibration and high reliability. This makes them particularly well-suited for sensitive applications such as infrared detectors, quantum computing systems, and space-based instruments, where mechanical disturbances must be minimized. They operate by generating oscillating pressure waves in a working gas, typically helium, which transfers heat through a regenerator and a pulse tube without the need for a mechanical displacer.

In contrast, GM cryocoolers use a mechanical displacer within the cold head to compress and expand helium gas, creating the cooling effect. This design introduces moving parts into the cold region, which leads to higher vibration and requires more frequent maintenance due to mechanical wear. However, GM cryocoolers are generally more efficient at certain temperature ranges and are widely used in applications such as MRI systems, cryopumps, and general-purpose laboratory cryostats. Their robust performance and relatively lower cost make them a popular choice for many industrial and research settings, despite the trade-offs in vibration and maintenance.

In summary, pulse tube cryocoolers offer greater reliability and minimal vibration, making them ideal for precision applications. In contrast, GM cryocoolers provide strong performance and cost-effectiveness for less vibration-sensitive environments.

What is the efficiency of a pulse tube cryocooler?

The efficiency of pulse tube cryocoolers is typically expressed as a percentage of the Carnot efficiency, which represents the theoretical maximum efficiency for a heat engine operating between two temperatures.

For single-stage pulse tube cryocoolers, typical efficiencies are:

- Around 10 to 20% of Carnot at temperatures near 80 K (e.g., for liquid nitrogen applications)

- Efficiencies as high as 24% of Carnot have been achieved at 80 K in optimized systems

- At lower temperatures (e.g., 4 K), the efficiency drops significantly, often to a few percent of Carnot, due to increased thermodynamic losses and limitations in regenerator performance.

These values are competitive with other cryocooler types, especially considering that pulse tube systems offer superior reliability and lower vibration due to the absence of moving parts in the cold head. While GM cryocoolers may offer slightly higher efficiency at some temperature ranges, pulse tube cryocoolers are often preferred in applications where mechanical simplicity and low vibration are more critical than marginal gains in efficiency.

Benefits of pulse tube cryocoolers

Pulse tube cryocoolers offer a range of benefits that make them highly attractive for applications requiring cryogenic temperatures, especially where reliability, low vibration, and minimal maintenance are critical. Here’s a breakdown of their key advantages:

1. No moving parts in the cold head

The most significant benefit of pulse tube cryocoolers is the absence of moving mechanical components in the cold region. This design drastically reduces mechanical wear and tear, leading to longer operational lifespans and lower maintenance requirements. It also eliminates the need for periodic displacer replacement, which is common in other cryocooler types like Gifford-McMahon systems.

2. Ultra-low vibration

Because there are no moving parts in the cold head, pulse tube cryocoolers generate extremely low vibration. This is crucial for vibration-sensitive applications such as:

- Infrared and optical detectors

- Quantum computing systems

- Scanning probe microscopy

- Space-based telescopes and instruments

3. High reliability and long life

The simplified mechanical design enhances reliability, making pulse tube cryocoolers ideal for long-duration missions or installations in remote or inaccessible locations. They are commonly used in aerospace and satellite systems where maintenance is not feasible.

4. Clean operation

Pulse tube cryocoolers are hermetically sealed and do not require lubricants in the cold region, reducing the risk of contamination. This makes them suitable for ultra-clean environments such as semiconductor fabrication and high-vacuum systems.

5. Scalability and versatility

Modern pulse tube designs can be scaled for a wide range of cooling powers—from milliwatts at 4 K to several watts at 77 K—making them suitable for both small-scale laboratory setups and large industrial systems.

6. Efficient thermal performance

While traditionally considered slightly less efficient than GM cryocoolers, advances in pulse tube design have significantly improved their thermal efficiency. They now offer competitive performance, especially in applications where vibration isolation and reliability outweigh marginal differences in efficiency.

7. Compatibility with closed-cycle systems

Pulse tube cryocoolers are fully compatible with closed-cycle refrigeration systems, eliminating the need for liquid cryogens like helium or nitrogen. This reduces operating costs and simplifies logistics, particularly in environments where cryogen supply is limited or impractical.