Sensors with Lead Extensions

Order sensors with lead extensions

Adding extra wire to your sensor leads can be cumbersome and time-consuming. Lake Shore offers this service at the time of order, allowing numerous options to best suit your application.

Lead extension summary

| Wire type | Wire material | Lead number | Insulation | Durability | Maximum temperature1 | AWG | Length | Can specify >450 K use |

|---|---|---|---|---|---|---|---|---|

| QL Quad-Lead™ | PhBr | 4-wire | Polyimide + Bond 999 | Durable ribbon cable | 433 K | 32 | 2 m, 5 m, or custom length | No |

| 36 | 2 m, 5 m, or custom length | No | ||||||

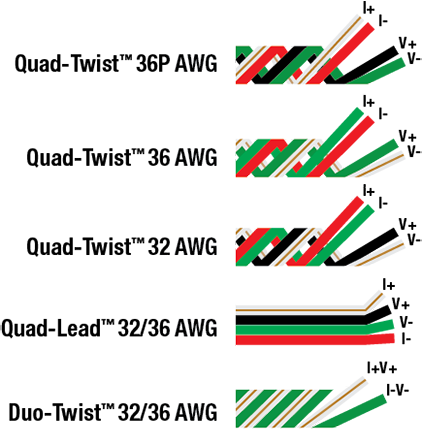

| QT Quad-Twist™ | PhBr | 4-wire | Polyimide | Rugged, medium wire flexibility | 500 K | 32 | 2 m, 5 m, or custom length | Yes (-H) |

| Formvar | Rugged, high wire flexibility | 378 K | 36 | 2 m, 5 m, or custom length | No | |||

| MW Manganin wire | Manganin | 4-wire | Formvar | Low wire flexibility | 378 K | 30 | 2 m, 5 m, or custom length | No |

| 32 | 2 m, 5 m, or custom length | No | ||||||

| 36 | 2 m, 5 m, or custom length | No | ||||||

| NM Non-magnetic wire | PhBr | 4-wire | Polyimide | Rugged, medium wire flexibility | 500 K | 32 | 2 m, 5 m, or custom length | Yes (-H) |

| Formvar | Rugged, high wire flexibility | 378 K | 36 | 2 m, 5 m, or custom length | No | |||

| DL Duo-Lead™ | PhBr | 2-wire | Polyimide + Bond 999 | Durable ribbon cable | 433 K | 36 | 2 m, 5 m, or custom length | No |

| DT Duo-Twist™ | PhBr | 2-wire | Polyimide | Rugged, medium wire flexibility | 500 K | 32 | 2 m, 5 m, or custom length | Yes (-H) |

| 36 | 2 m, 5 m, or custom length | Yes (-H) | ||||||

| DM Manganin wire | Manganin | 2-wire | Formvar | Low wire flexibility | 378 K | 30 | 2 m, 5 m, or custom length | No |

| 32 | 2 m, 5 m, or custom length | No | ||||||

| 36 | 2 m, 5 m, or custom length | No | ||||||

| DN Non-magnetic wire | PhBr | 2-wire | Polyimide | Rugged, medium wire flexibility | 500 K | 32 | 2 m, 5 m, or custom length | Yes (-H) |

| Formvar | Rugged, high wire flexibility | 378 K | 36 | 2 m, 5 m, or custom length | No | |||

| Delicate, high wire flexibility | 42 | 2 m, 5 m, or custom length | No |

1Standard leads are attached with 63//37 SnPb solder, intended for use below 450 K. If the sensor is to be used between 450 K and 500 K, higher temperature 90/10 PbSn solder is required. All lead extension soldering is performed to J-STD-001 Class 2 quality standard.

2Phosphor-bronze has comparable thermal conductivity levels to manganin when 42 AWG is used. Note this ultra-thin version is extremely delicate and recommended only for experienced users.

Recommended configurations

| Part number | Application | Configuration | Wire type | Insulation | Gauge |

|---|---|---|---|---|---|

| -QL | Situations where ease-of-use and ruggedness is important | QL (Quad-Lead) Wire is easy to heat sink due to its ribbon structure | PhBr Rugged and flexible | Polyimide Strong, solvent-resistant, high temperature rating | 32 AWG Easier to prepare and solder than thinner gauges |

| -QT | Noisy environments where signal integrity must be protected | QT (Quad-Twist) Helps reject electromagnetic interference | PhBr Rugged and flexible | Formvar Abrasion resistant, wire flexibility (not solvent resistant) | 36 AWG Reduces thermal conductivity and heat leak |

Wire material

Phosphor-bronze is the most common cryogenic wire, offering low thermal conductivity, moderate resistance, and excellent magnetic field stability—ideal for magnet environments and multi-lead setups. It’s rugged and flexible, especially in twisted or ribbon formats. Manganin provides lower thermal conductivity and copper-matched thermal expansion, making it suitable for applications with thermal cycling, but it’s less flexible due to its insulation and single-strand form.

| Property | Phosphor-bronze (PhBr) | Manganin |

|---|---|---|

| Best use case | General-purpose cryogenic wiring, especially in magnetic fields and multi-lead setups | Precision applications needing copper-matched expansion and minimal heat leak |

| Durability and handling | Rugged and flexible | Less flexible |

| Thermal conductivity | Low3 | Very low — minimal heat leak |

| Electrical resistance | Moderate – less signal noise | High |

| Magnetoresistance | Very low – best for magnetic fields | Low |

| Magnetic properties | Non-ferromagnetic | Non-ferromagnetic |

| Maximum temperature | 500 K | 378 K |

| Available wire gauges (AWG) | 32, 36, 42 | 30, 32, 36 |

| Thermal expansion | Not closely matched to copper | Very close to copper—reduces mechanical stress in thermal cycling |

3Phosphor-bronze has comparable thermal conductivity levels to manganin when 42 AWG is used. Note this ultra-thin version is extremely delicate and recommended only for experienced users.

Wire gauge

The wire gauge selection process usually involves a compromise between thermal conductivity and ease-of-use, with thinner wire being preferred to reduce thermal conductivity and thicker wire being easier to handle and work with. 32 and 36 AWG are our preferred wire gauges to use because they provide the best balance between reduced thermal conductivity and ease-of-use.

| AWG | Diameter | Material | Recommendation |

|---|---|---|---|

| 30 | 0.01 in (0.255 mm) | Manganin | Only use when required |

| 32 | 0.00795 in (0.202 mm) | PhBr, manganin | Recommended |

| 36 | 0.0055 in (0.127 mm) | PhBr, manganin | Recommended |

| 42 | 0.0025 in (0.0635 mm) | PhBr | Only use when required |

Wire insulation

Polyimide is the most versatile cryogenic wire insulation, offering high thermal and radiation resistance, excellent chemical durability, and rugged mechanical performance—ideal for harsh environments like space or high-energy labs. Formvar® is highly flexible and abrasion-resistant, making it great for tight bends at ultra-low temperatures, though it’s sensitive to solvents and requires careful handling; it should be given an annealing preheat prior to varnish application. Polyimide with Bond 999 builds on standard polyimide’s strengths with enhanced bonding properties, ideal for applications needing strong mechanical adhesion or thermal bonding. Both polyimide and Formvar can be removed mechanically during terminal preparation.

| Property | Polyimide | Formvar® (polyvinyl formal) |

|---|---|---|

| Best use case | Most versatile; widely used | Ideal for tight bends at cryogenic temperatures |

| Chemical resistance | Excellent — resists solvents and burnout | Poor — crazes with solvents like toluene, xylol, and naphtha |

| Radiation resistance | Excellent | Not rated for radiation |

| Mechanical properties | Rugged | Flexible and abrasion‑resistant |

| Voltage rating (32/36 AWG) | 3525/2525 VAC | 3525/2525 VAC |

Ordering information

| -XX Wire type | -YY Wire gauge | -Z Length (m) | -H >450 K | Ordering part number |

|---|---|---|---|---|

| QL Quad-Lead™ | 32 | 2 m 5 m Custom | — | Recommended (-QL) -QL-32-5 -QL-32-Z |

| 36 | 2 m 5 m Custom | — | -QL-36-2 -QL-36-5 -QL-36-Z | |

| QT Quad-Twist™ | 32 | 2 m 5 m Custom | -H | -QT-32-2(-H) -QT-32-5(-H) -QT-32-Z(-H) |

| 36 | 2 m 5 m Custom | — | Recommended (-QT) -QT-36-5 -QT-36-Z | |

| MW Manganin wire | 30 | 2 m 5 m Custom | — | -MW-30-2 -MW-30-5 -MW-30-Z |

| 32 | 2 m 5 m Custom | — | -MW-32-2 -MW-32-5 -MW-32-Z | |

| 36 | 2 m 5 m Custom | — | -MW-36-2 -MW-36-5 -MW-36-Z | |

| NM Non-magnetic wire | 32 | 2 m 5 m Custom | -H | -NM-32-2(-H) -NM-32-5(-H) -NM-32-Z(-H) |

| 36 | 2 m 5 m Custom | — | -NM-36-2 -NM-36-5 -NM-36-Z | |

| DL Duo-Lead™ | 36 | 2 m 5 m Custom | — | -DL-36-2 -DL-36-5 -DL-36-Z |

| DT Duo-Twist™ | 32 | 2 m 5 m Custom | -H | -DT-32-2(-H) -DT-32-5(-H) -DT-32-Z(-H) |

| 36 | 2 m 5 m Custom | -H | -DT-36-2(-H) -DT-36-5(-H) -DT-36-Z(-H) | |

| DM Manganin wire | 30 | 2 m 5 m Custom | — | -DM-30-2 -DM-30-5 -DM-30-Z |

| 32 | 2 m 5 m Custom | — | -DM-32-2 -DM-32-5 -DM-32-Z | |

| 36 | 2 m 5 m Custom | — | -DM-36-2 -DM-36-5 -DM-36-Z | |

| DN Non-magnetic wire | 32 | 2 m 5 m Custom | -H | -DN-32-2(-H) -DN-32-5(-H) -DN-32-Z(-H) |

| 36 | 2 m 5 m Custom | — | -DN-36-2 -DN-36-5 -DN-36-Z | |

| 42 | 2 m 5 m Custom | — | -DN-42-2 -DN-42-5 -DN-42-Z |