More about the Model 224

Configure each input independently

Because the Model 224 features 12 independently configurable 6-pin DIN inputs, you can set it up for a different sensor on each input and run a number of different measurements simultaneously for various critical points in a system. Two inputs (A and B) are dedicated and non-scanned, updated at 10 rdg/s. The remaining 10 are scanned channels—inputs C and D can have up to five input devices each. These scanned channels are read anywhere from 1 to 10 rdg/s, depending on how many are being used at once.

The Model 224 features four high-resolution, 24-bit analog-to-digital converters for fast measurements. Optical isolation of input circuitry reduces line noise—interference that can skew low-level measurements—while providing repeatable sensor measurements.

Current reversal eliminates thermal electromotive force (EMF) errors when using resistance sensors. Also, nine excitation currents enable temperature measurements down to 300 mK when you use the appropriate NTC RTDs. When autoranging is enabled, the range will be automatically selected so that the excitation voltage is below 10 mV. This keeps the power dissipated in the sensor at a minimum, yet still at enough of a level to provide accurate measurements.

Monitor locally or remotely—from anywhere

For local monitoring, the front panel of the Model 224 features a bright liquid crystal display with an LED backlight that shows up to 12 readings simultaneously, or, you can even display a single sensor input to see greater detail at a glance.

Plus, monitoring can be done over a network. Using the Ethernet port on the Model 224, you can keep an eye on temperatures and log measurement data remotely via a networked local PC or even remotely over a TCP/IP Internet connection from anywhere. A chart recorder utility embedded in the Ethernet module enables real-time charting of temperatures using a convenient graphical interface. You can also interface with the temperature monitor or link it to a data acquisition system via its serial USB or parallel IEEE-488 ports.

Intuitive, configurable display

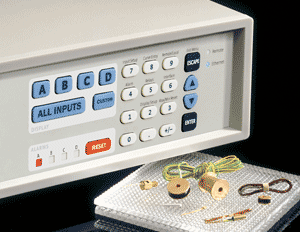

The Model 224 front panel features a 23-key keypad and intuitive user interface for easy navigation of the temperature monitor’s functions.

For added convenience, you can also custom label each sensor input, eliminating the guesswork in remembering or determining the location to which a sensor input is associated.

Stores response curves

Like the Lake Shore Model 336, the Model 224 includes standard temperature sensor calibration curves for silicon diodes, platinum RTDs, and Rox™ (ruthenium oxide) RTDs.

The monitor’s non-volatile memory enables users to store up to 39 200-point CalCurves for Lake Shore calibrated sensors or user curves. Lake Shore also offers curve handler software, which allows you to upload and manipulate temperature sensor calibration data.

And for applications requiring more accuracy than what’s available using the built-in sensor curves, the Model 224 includes the Lake Shore SoftCal™ algorithm. It generates curves for silicon diodes and platinum RTDs for storage as user curves.

Ideal applications

- Labs with multiple temperature sensors

- Applications where both cryogenic and higher temperature readings are required

- Monitoring of simple Dewars and LN cryostats (>4.2 K)

- Closed-cycle refrigerators (CCRs) at 3 K to 4 K

- Pumped He-4 (1.4 K) and He-3 (300 mK) systems

- Temperature monitoring where superconducting magnets are used, such as in mass spectrometer and particle accelerator equipment

Perfect for use with our high-performance and versatile Cernox® sensors

Perfect for use with our high-performance and versatile Cernox® sensors

While the Model 224 accepts a wide variety of sensors, it is especially well suited to work with Lake Shore Cernox sensors. These thin-film resistance cryogenic sensors offer significant advantages over diodes and conventional RTD sensors. The smaller package size makes them useful in a wide range of experimental mounting schemes, and they’re also available in a chip form.