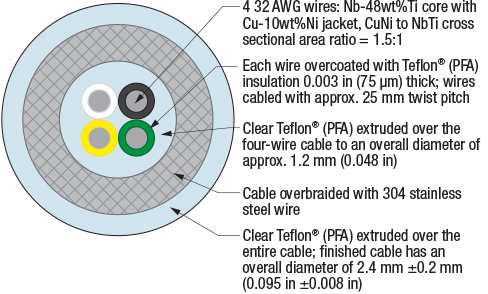

CryoCable™ is a robust, 4-wire cable for use in cryogenic environments to room temperature. The cable is designed around 32 AWG (203 µm) diameter superconductive wires consisting of a NbTi core (128 µm

diameter) and a Cu-10% Ni jacket.

Minimum bend radius: 15 mm (0.6 in)

Critical temperature: 9.8 K

Critical field: 10 T

| Field | Critical current (per wire) |

| 3 T | 35 A |

| 5 T | 25 A |

| 7 T | 15 A |

| 9 T | 6 A |

| | Temperature (K) |

| 295 | 77 | 4.2 |

| Wire resistance (Ω/m) | 9.2 | 8.4 | 010 |

| Overbraid resistance (Ω/m) | 0.90 | 0.64 | 0.62 |

| Thermal conductivity — entire cable assembly (W/(m•K)) | 7.6 | 2.8 | 0.17 |

10 Superconducting