Dilution Refrigerator Temperature Control

Making accurate measurements at ultra-low temperatures is no easy feat, especially when working in the ranges seen by modern dilution refrigerators. The Model 372 has many features specifically developed for dilution refrigerator applications.

Dedicated temperature control input

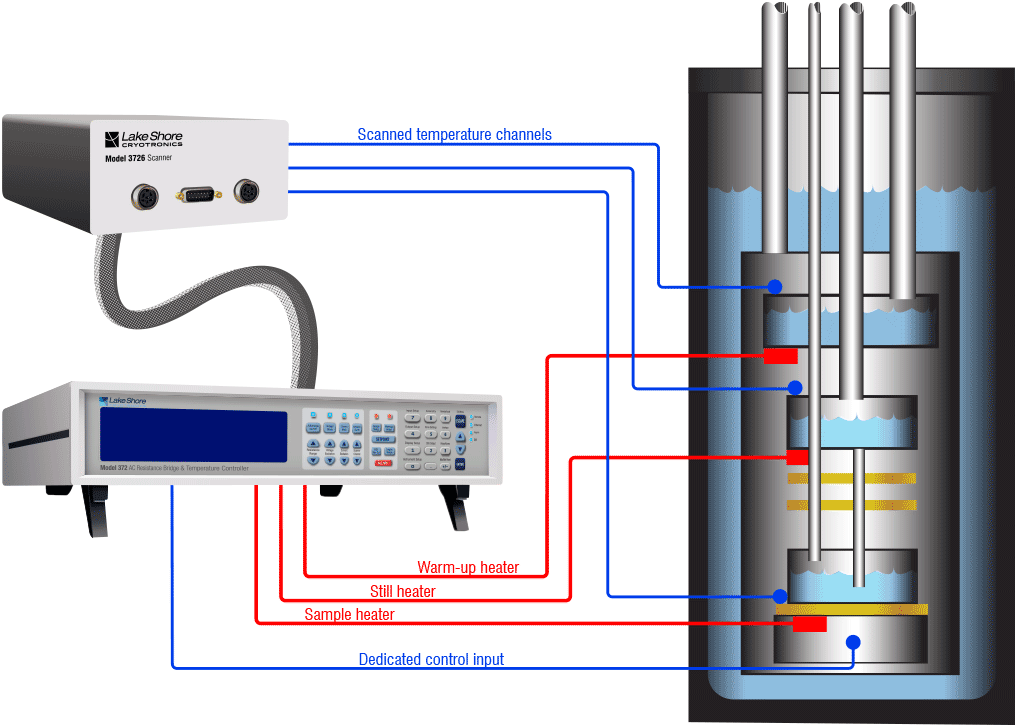

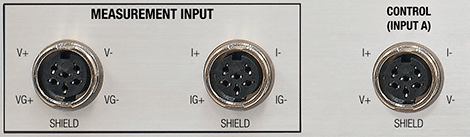

Taking measurements at ultra-low temperatures deserves uninterrupted attention from measurement devices. The Model 372 uses a dedicated temperature control input that is designed specifically for connection to a negative temperature coefficient resistive sensor. This input is designed to continuously monitor the temperature of the dilution refrigerator sample holder, while the measurement input scans through the multiple other temperature sensors placed throughout the dilution refrigerator.

The dedicated control input ensures uninterrupted dilution refrigerator temperature control

|

Stable temperature control

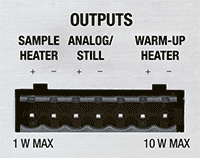

When operating at ultra-low temperatures, even small amounts of added energy can cause unwanted spikes in system temperature. The Model 372 heater outputs implement several protection mechanisms to reduce or eliminate this potential:

- The circuitry for the sample and still heaters are electrically isolated from other instrument sections

- Multiple power range settings allow extremely fine or coarse power transitions, depending on the need

- Heater outputs are shunted during power up and power range changes, eliminating the potential for unwanted power surges

- Terminal connections allow twisted pair cabling to be easily used for heater wiring; additional shielding of these wires can also be added to further reduce the potential of injecting noise into a system via the heater cabling

Temperature zone control

Thermal response characteristics of a dilution refrigerator system can change quite dramatically over the useful range of operation, particularly down towards the lower temperature limit of a system, where cooling power is reduced. To accommodate these system variations, different PID values can be set for different temperature ranges (zones). This allows for more aggressive transition settings to be used at higher temperatures where system response is faster, and less reactive settings at low temperatures when temperature overshoots result in long recovery times.

Heater fail-safes

The Model 372 has several features that will protect your system and experiment from accidental deviations in planned temperature settings:

- Temperature thresholds can be set for all heater outputs, meaning the heaters will automatically shut down if it is detected that the system is being overheated.

- An easy-to-hit “ALL OFF” button is provided that shuts all heaters down instantly. This eliminates the terrible experience of having to hurriedly search through menu options while your experiment continues to heat.